|

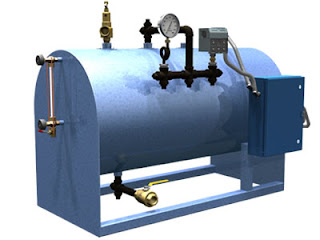

| Industrial Boiler |

There, fortunately, is a single solution that can help to attain useful goals with the three concerns of safety, fuel cost, and regulatory compliance. Applying an efficiency controller to manage the fuel to air ratio of the combustion system will deliver benefits far in excess of the cost to incorporate the necessary devices. The three basic goals for the fuel air controller are:

- Maximize fuel efficiency

- Minimize regulated emissions

- Maintain safe operating condition

A good portion of all three goals can be accomplished through careful concerted parallel control of combustion air supply and fuel supply. The fuel air ratio must be subject to continual adjustment in response to current air conditions (which can vary on a daily basis) and the level of O2 in the flue gas. Controlling the air fuel ratio supports the following goals:

- Preventing excess fuel vapors from entering the flue and creating an unsafe condition

- Providing the correct amount of air to effectively combust the fuel supplied to the burner

- Preventing excess air flow from reducing net heat transfer to the feedwater

- Maintaining regulated emissions within required limits

- Limiting fuel consumption to the minimum necessary to meet demand

Fireye® is a leading manufacturer of flame safeguard controls and burner management systems for commercial and industrial applications throughout the world. Their products, the first of which was developed in the 1930's, enhance the safety and efficiency of all fuel fired burners.

There are numerous capabilities built in to the company's PPC4000 series of fuel air ratio controllers. Some of the more notable include:

- Precise fuel air ratio attained using parallel control of servos to regulate fuel and air supplies.

- User selected burner profiles

- Alarm contacts

- PID operation

- An array of inputs and outputs to accommodate sensors and devices needed to monitor and control boiler operation

- Compatible with other products that provide additional flame and burner monitoring safety

- Multiple boiler sequencing and cold start thermal shock protection

- On board boiler efficiency calculation

- User interface, optional larger touchscreen interface

Glance through just the first two pages of the document below to get a full description of the capability of this compact and comprehensive controller. You can get more detailed information, or get a professional evaluation of your current system efficiency, by contacting the combustion experts at CTi Controltech.