|

| High performance butterfly valves handle challenging media and process conditions. Image courtesy Flowserve - Valtek Control Products |

Industrial valves intended for extreme applications are generally referred to as severe service or high performance valves. While there are plenty of published and accepted standards for industrial valves, one does not exist to precisely define what constitutes a severe service valve.

So, how do you know when to focus valve selection activities on severe service or high performance valves, as opposed to those rated for general purpose? There are a number of basic criteria that might point you in that direction:

- Extreme media or environmental temperature or pressure

- High pressure drop operation that may cause cavitation

- Rapid or extreme changes to inlet pressure

- Certain types or amounts of solids contained in the fluid

- Corrosive media

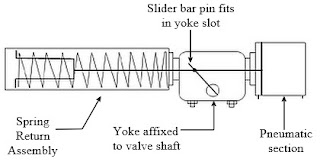

There are numerous manufacturers of severe service or high performance valves, each with specialized product offerings focusing on a particular performance niche. Flowserve, under their Valtek brand, manufactures the Valdisk high performance butterfly valves ranging from NPS 2-52 and ASME class 150, 300, 600, 900, 1500 pressure ranges. The valve design is ideal for manual or automated actuation, installed with a manual hand gear, electric actuator, or a pneumatic actuator. Seats are available as soft or metal on this double offset butterfly valve that provides tight closure for bi-directional flow. Construction materials include carbon steel and stainless steel. A range of options and variants are available to customize the valve build to suit a replacement or new installation.

There is more information available about the Valtek high performance valve offering. Share and discuss your special requirements with a valve specialist. They have application experience and access to technical resources that can leverage your own process knowledge and experience into an effective solution.