|

| Scotch Yoke Pneumatic Valve Actuator Courtesy Flowserve - Automax |

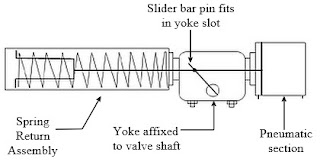

Quarter turn valves, such and ball, plug, or butterfly valves, only require a 90 degree rotation from their fully closed to fully open positions. In this case, the Scotch yoke is not used to produce continuous rotating motion, as it may in some engine applications. For the valve actuation case, the Scotch yoke functions much like a hand on a lever. The pneumatic variants use air pressure to drive the slider in one direction until a preset stop position is reached. Usually, a spring provides a counterforce that will drive the valve to a desired fail-safe stop position in the absence of air pressure. Other combinations of driving force and fail-safe operation are available to suit differing application needs.

|

| Diagrammatic representation of Scotch yoke valve actuator Illustration excerpted from Automax RG Standard Pneumatic Valve Actuator IOM with text added |

Selecting and configuring the right actuator and valve for any application benefits from consultation and cooperation among the process engineers and valve automation specialists. Share your process valve and automation challenges with experienced professionals, combining your own process knowledge and experience with their product application expertise to produce an effective solution.