|

Cutaway View of Industrial Ball Valve

Courtesy of Flowserve Atomac |

Industrial fluid handling and process control rely on valves to regulate the pressure and control the flow rate and direction of a wide variety of liquids and gases. There can be highly sensitive or specialized performance requirements, along with additional needs for corrosion resistance and an ability to withstand extreme fluid or environmental temperatures. Selecting the proper valve can be a challenging and time consuming operation for a new or updated process. Taking an initial step of narrowing the field of potential candidates to those with basic operational and construction characteristics that will be advantageous to your process requirements will move you quickly toward an effective selection.

Industrial valves for flow control are often grouped and referred to by their closure mechanisms. Common types include ball, plug, butterfly, globe, and gate. Each type has attributes making it more suitable to certain applications. Start your selection process by choosing a valve type that will provide the type of service needed. Let’s look at ball valves.

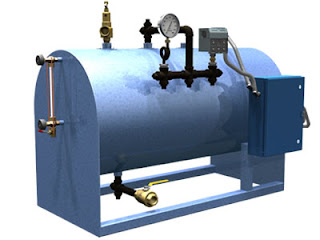

Ball valves are named for the generally spherical shaped element encased in the valve body and placed directly in the fluid flow path. The ball has a hole, or port, through it’s center that allows fluid to pass when the port is aligned with the direction of flow. The stem, attached to the ball and extending to the exterior of the valve body, that can be rotated through a 90 degree arc manually, or utilizing a powered actuator. At one extreme of the arc, the port is perpendicular to the flow path and fluid flow is completely obstructed and shut off. Rotating the stem ninety degrees from the closed position will align the port with the flow direction in the fully open position.

What are some potential advantages of ball valves?

|

Interior of Ball Valve

Courtesy of Mogas Industries |

- Well suited for applications requiring either full flow or no flow.

- Quarter turn operation provides a rapid transition from open to closed position.

- Leak-proof service.

- Force required to drive the valve stem is comparatively moderate.

- No lubrication required and maintenance is minimal.

- Comparatively light weight and compact, reduced installation space and support requirements.

- When fully open, the port provides little resistance to flow with a straight through path.

What are some potentially concerning attributes?

- Residual amounts of the process fluid may be trapped in the port when the valve is closed, then released to the fluid stream when the valve is opened. Potential contamination impact should be considered.

- Ball valves are not well suited for throttling of the flow. Partially open ball valves expose seals and sealing surfaces to effects of the fluid velocity and potentially corrosive nature of the fluid. Additionally, the basic construction and operation of the ball and port generally do not provide variable flow control as well as some other valve types.

- Valve seals, most often elastomertic materials, may not be compatible with fluid characteristics. Consider temperature, corrosiveness, and other fluid characteristics for compatibility with the seal material.

These general points are intended to get you thinking about your valve application in a productive and efficient manner. There may be particular ball valve variants that overcome potential shortcomings listed in this article. Talk to a

valve specialist about your application. Their recommendation, based upon high level product knowledge and experience with numerous applications, will be a valuable addition to your decision making.