|

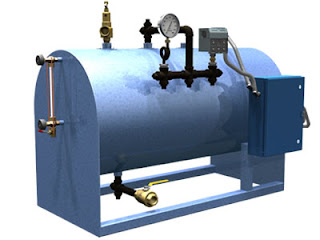

| Electric Boiler Courtesy Williams & Davis Boilers |

Electric boilers are comparatively simple devices. They will resemble their combustion heated cousins in practically all aspects related to the the handling of water and steam. Where they differ is the means of heating.

Electric boilers have bundles of electric heaters immersed in the water to be converted to steam. Electrical switching gear and controls that regulate the operation of the heaters in response to steam demand will likely be mounted integrally to the unit. What will be missing is all the hardware needed for fuel storage, delivery, regulation, and ignition, along with a host of other items needed for the presence and handling of a combustible fuel supply and removal of the products of fuel combustion.

Let's look at some points that may prove advantageous for an electric boiler installation.

|

| Cutaway View of Electric Boiler Courtesy Williams & Davis Boilers |

- Small steam requirements: Installations with highly localized or small scale requirements for steam may benefit from the lower complexity of an electric boiler installation.

- Intermittent operation: Electric boilers are very easy to start and stop.

- Shortened project timeline: The installation of an electric boiler generally does not have as many infrastructure requirements as those utilizing combustible fuels, allowing for reduced time between project inception and completion.

- Reduced installation costs: No need for the provision or storage of combustible fuel and the associated operational and safety infrastructure. In some jurisdictions, it is permissible to locate an electric boiler in proximity to the steam consuming device, reducing costs for piping.

- Reduced maintenance requirements: Electric boilers have almost no moving parts, no flue, no burners, no fuel system, and none of the hardware, maintenance, or regular inspections associated with combustion safety.

- Operation of electric boilers is comparatively quiet.

If your application can benefit from some of these potential advantages of electric boiler installation, an analysis of the longer term costs may be in order. The generally reduced energy cost of combustion based systems may, at some point, make them a better choice. With your steam production and demand requirements in hand, contact a boiler specialist that can provide both electric and combustion heated systems and chart out the tangible and intangible benefits of several options. The right choice will be revealed with a careful analysis.